Digital Factory

High Quality

Product & Mould

Cost Control

Direct Cose , Indirect Cost

On-time Delivery

Samples, Parts

Best Service

Customers, Employees, Suppliers

Form

IATF16949 Certificate

SAP System

SAP Control

Process

Project Management

Standardization

Performance Management

Information Management

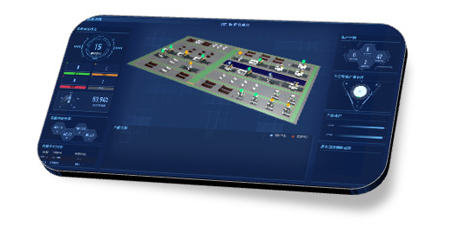

Equipment data collection requirements and problems to be solved

Accurately Count Equipment OEE

Through manual meter reading, it is transformed into intelligent statistics to improve timeliness and accuracy!

Provide data support for equipment maintenance prediction

Monitor and output equipment alarm information to provide data support for equipment maintenance!

Remotely track equipment operating status

The remote monitoring of workshop equipment is realized through the cloud, and the real-time running status of each machine can be grasped in time, and the abnormal situations such as alarms and faults can be responded and handled in time!

Improve night shift work efficiency

Improve the work awareness of night shift operators through the equipment operation status, and improve the operation efficiency and work efficiency of night shift equipment!

Production report data matching check

The operation data collected by the equipment and the production report data form a correlation and comparison, realize the effective analysis of the report time, and provide data support for further in-depth performance appraisal!