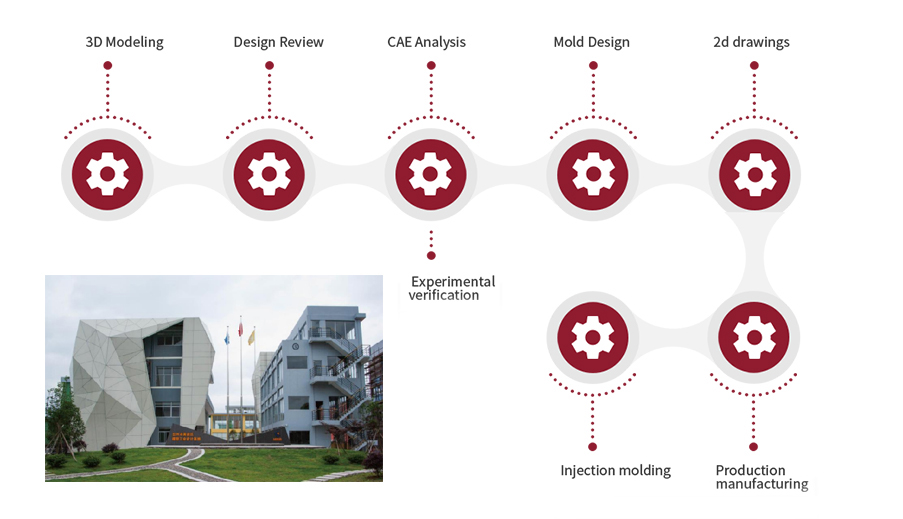

Innovative Technology

Strong industrial design

Create a new ecosystem in the industry

Kaihua automotive technology design originated from Kaihua Group

Focus on industrial product design.

Integrating the advantages of Kaihua Automotive Technology in finite element simulation technology, by integrating design, simulation and manufacturing, it creates a new ecosystem in the industry and provides customers with a full range of services.

Innovative mold and process technology provide guarantee for low cost and high efficiency of parts manufacturing

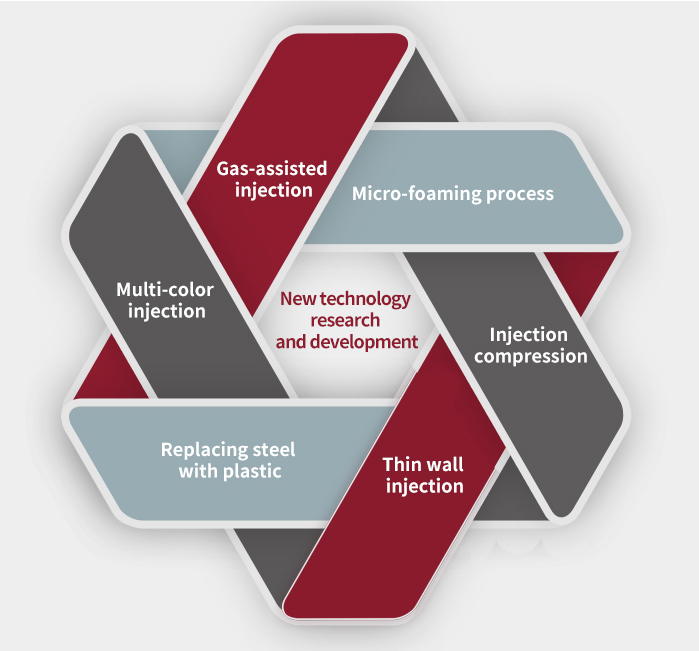

Technical Features

Microfoam

Shorten molding cycle, prevent product surface shrinkage and reduce product weight

Stack mold

Increase throughput and reduce production and injection molding costs

Thin wall injection

Reduce production costs and reduce product weight

Replacing steel with plastic

Reduce weight and reduce production costs

Multi-color high-gloss injection molding

Two-color, three-color injection molding, high-gloss two-color injection molding

Gas assist

Reduce production costs and improve product appearance

Injection Compression Molding

Eliminate internal stress, good light transmission

| Name | Advantage | Application products |

| Gas-assisted injection | Reduce production costs and improve product appearance | Passenger handle |

| Replacing steel with plastic | Reduce weight and reduce production costs | Injection bracket |

| Bicolor/Tricolor/Highlight | Reduce costs and improve product appearance | Ventilation covers, cabin trim panels, light trim panels |

| Chemical/Physical Foaming | Shorten molding cycle, prevent product surface shrinkage, and reduce product weight | Air ducts, injection molding guards, structural parts |

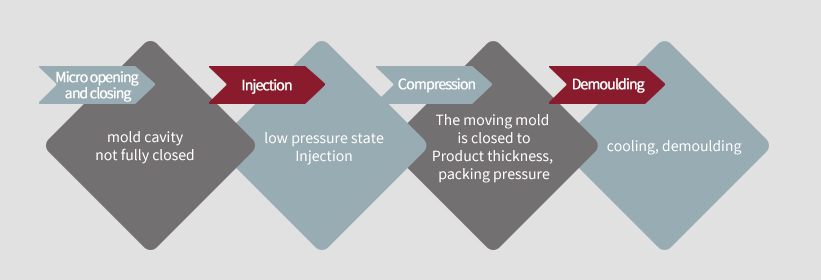

| Injection Compression Molding | Reduce internal stress, reduce clamping force and injection pressure, and improve production efficiency | Optical lens, injection glass |

Innovative Technology - Microfoam Injection Molding

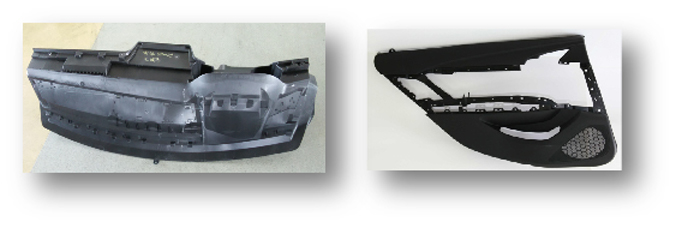

Microfoam Injection Molding Applicatio

Door panel

Tailgate

Dashboard Skeleton

...

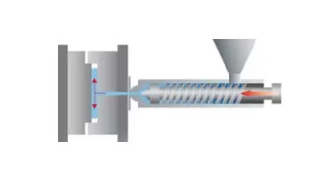

Chemical method

Indirect gas formation

Foaming masterbatch

Physical law

Direct gas injection

Inert gases such as N2 and CO2

| Advantage | Chemical method (open mold) | Physical Law (Under Note) |

| Principle | After injection, the mold retreats and foams | Filling the mold with foam expansion |

| Schematic |  |

|

| Weight loss ratio | 20%~35% | 10%~15% |

| Injection molding process | High-speed filling, mold opening, and shorter cycle times | Same as traditional injection molding with shorter cycle times |

| Energy consumption | Reduce | Reduce |

| Mold design | Thin Wall Design | Traditional Design Optimization |

| Equipment requirements | Retrofit of traditional equipment, closed nozzle | Conventional equipment, closed nozzle |

| Mass production impact | Normal production, special mold | Normal production, general mold |

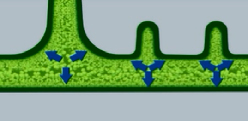

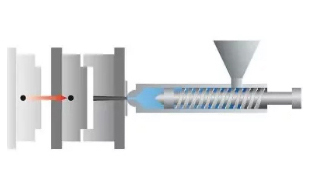

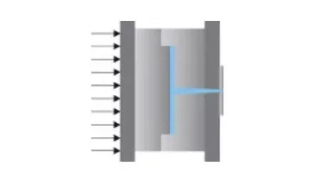

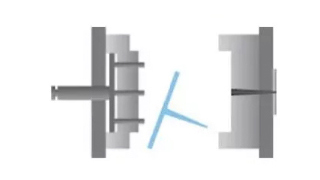

Innovative Technology - Injection Compression Molding

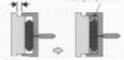

1. Clamp the mold to the edge of the row cavity

2. Injection of molten plastic

3. Compression injection into molten plastic

4. Cooling and stripping

Advantage

The moving model pushes the entire cavity and completes the pressure-holding action

The pressure established in the cavity is evenly distributed on the surface of the product

Greatly improve the precision and dimensional stability of the surface of the product

Low internal stress during injection molding, suitable for parts with high transparency requirements